1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

+86-18682200597

+86-18682200597

sales@szhaiwang.com

sales@szhaiwang.com

1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

+86-18682200597

+86-18682200597

sales@szhaiwang.com

sales@szhaiwang.com

(1) Usage: According to the principle of photoelectric control, it automatically controls the working status of the product with changes in external light

(2) Performance: A. Epoxy resin; B. Fast reaction speed;

C. High sensitivity; D. Small volume;

E. Good reliability; F. Good spectral characteristics;

(3)Main material composition: CdS, CdSe, epoxy resin, ceramic substrate, tinned copper wire.

Online consultation

Online consultation

▲Application

Camera, automatic metering, photoelectric control, indoor light control

Alarm industrial control, light control switches, light control lamps, electronic toys, etc

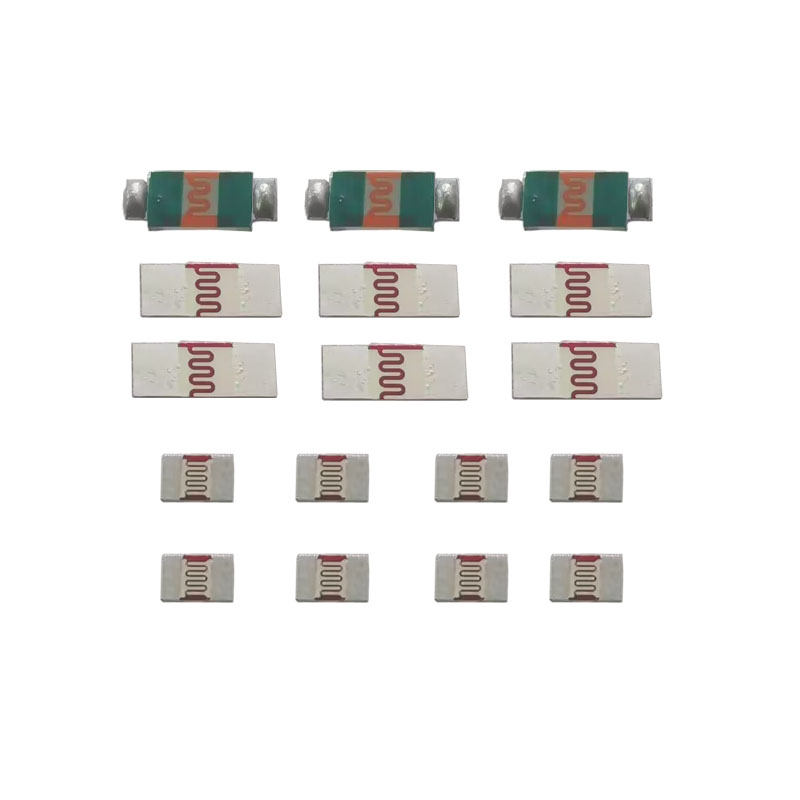

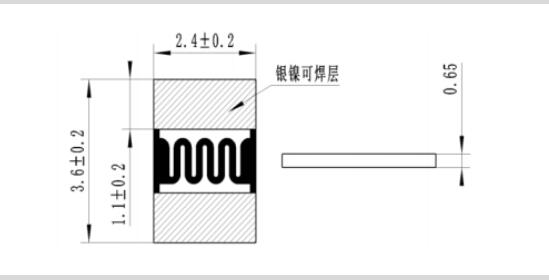

▲Dimension(mm)

▲Specifications and models

specifications | Type | Max. Voltage(VCD) | Max. power consumption(MW) | ambient temperature(℃) | Spectral peak (nm) | Light resistance(kΩ) | Dark resistance (MΩ) | r 100/10 |

SMD Photocells Series | MJ36516 | 60 | 50 | -30~+70 | 560 | 5-10 | 0.5 | 0.65 |

M36528 | 60 | 50 | -30~+70 | 560 | 8-20 | 1 | 0.7 | |

MJ36537 | 100 | 50 | -30~+70 | 560 | 18-50 | 2 | 0.7 | |

MJ36549 | 100 | 50 | -30~+70 | 560 | 50-150 | 5 | 0.8 |

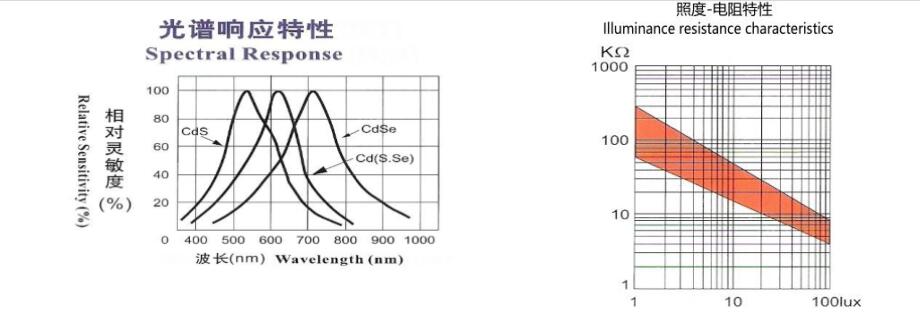

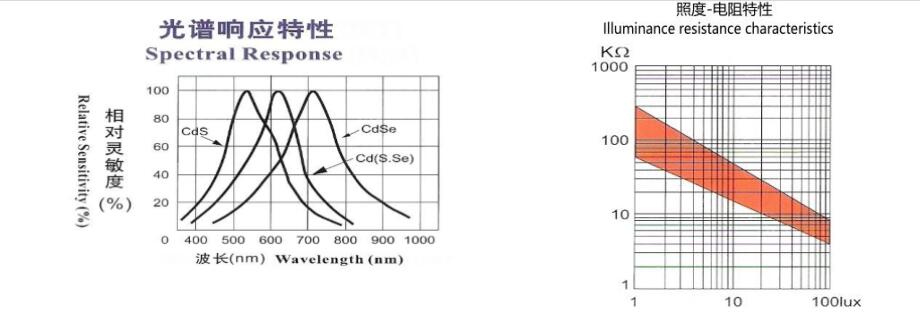

▲Spectral characteristics and illuminance resistance characteristics

▲Test conditions

(1) Luminous resistance: After being irradiated with 400-600Lux light for 2 hours, measure with 10Lux light under standard light source A (color temperature 2856K).

(2) Dark resistance: The resistance value at the 10th second after turning off 10Lux light.

(3) The Y value refers to the standard value under 10Lux illumination and 100Lux illumination Resistance values of R10 and R100 under illumination of 10Lux and 100Lux, respectively.

(4) Wire bending degree: Any bending of the wire is carried out without any breakage or damage found.

(5) Vibration: Place the photoresistor on the vibrator and vibrate for two hours. No damage was found.

(6) Voltage withstand: Apply a 200V DC voltage to both ends of the photoresistor in the dark state, without any abnormal phenomena.

(7) Moisture and high temperature resistance: When working at a humidity of 75 and a temperature of 70 ℃, the resistance change rate is less than ± 10% When stored at a humidity of 75 ° C and a temperature of 80 ° C, its resistance change rate is less than ± 10%.

(8) Impact resistance: Place the photoresistor at 80 ℃ for 4 hours, then at 25 ℃ for 2 hours, and then at -30 ℃ for 4 hours. The rate of change in resistance before and after placing the photoresistor is less than ± 10%.

▲Precautions

1.The photoresist contains cadmium (Cd), which does not comply with ROHS. If youmust have environmentally friendly photosensitive elements, you can choose thephotosensitive sensor series of Shenzhen Jingchuang Heli Technology Co., Ltd

2.Storage environment: - 30-50℃, dry and protected from light to avoidpin oxidation.

3.During welding, the distance between the welding spot and the photoresist body shall bemore than 3mm. So as not to damage the product at high temperature.

4.During welding, the temperature shall not be too high and the welding time at shall notbe too long (no more than 3 seconds). So as not to damage the product high temperature.

szhaiwang4@hotmail.com

+86-18682200597

sales@szhaiwang.com